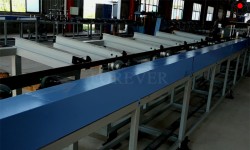

Bar induction heating furnace

Features:

1.Application:Heat Treatment for Bars,Pipes,Billet,Slab,Shaft,Bearing,Strip,Wire

2.Available Power:100KW-10000KW

3.Non-standard Product:Professional Customization

Product Detail

Application Video

Product Tags

Specializing in producing induction bar heating furnace, Forever Furnace can provide process design and process equipment of induction heating according to customer’s bar heating furnace parameters. In addition, we have 20 years of experience in the field of bar heating furnace and can give you the perfect solutions and thoughtful service.

Advantages for bar induction heating furnace

1.Fast heating speed.You needn’t preheat the equipment like other machines,so your material can be heated rapidly.And the oxidization burning loss rate of the bloom is only 0.5%-1%.

2.High induction heating efficiency.The induction heating efficiency can be up to 70%.

3.Improve the labors working environment greatly.With electromagnetic induction heating principle,there is almost no dust,exhaust gas or heat loss.

4.Fast heating speed can improve production efficiency greatly.It can work with other equipment in the production line.

Forever Furnace Service Commitment for Bar Induction Heating Furnace

1″1+2″service mode, that is one sales person and one after-sales person will serve you once you buy our bar heating furnace.

2.Free field installing and adjusting bar heating furnace.Responsible for training to the operator and maintenance personal.

3.Provide the whole technical information including circuit diagram.

4.Give response within 24 hours once receiving users’ call or email.

Forever Furnace can provide the complete set of bar induction heating system including bar heating furnace,medium frequency power supply,automatic feeding and discharging device, Siemens PLC control system and so on.Welcome your inquiry!

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.